NEWS

Federal Specification GGG-P-463c and ASME B89.3.7-2013.

Writer: admin Time:2020-12-05 20:20 Browse:℃

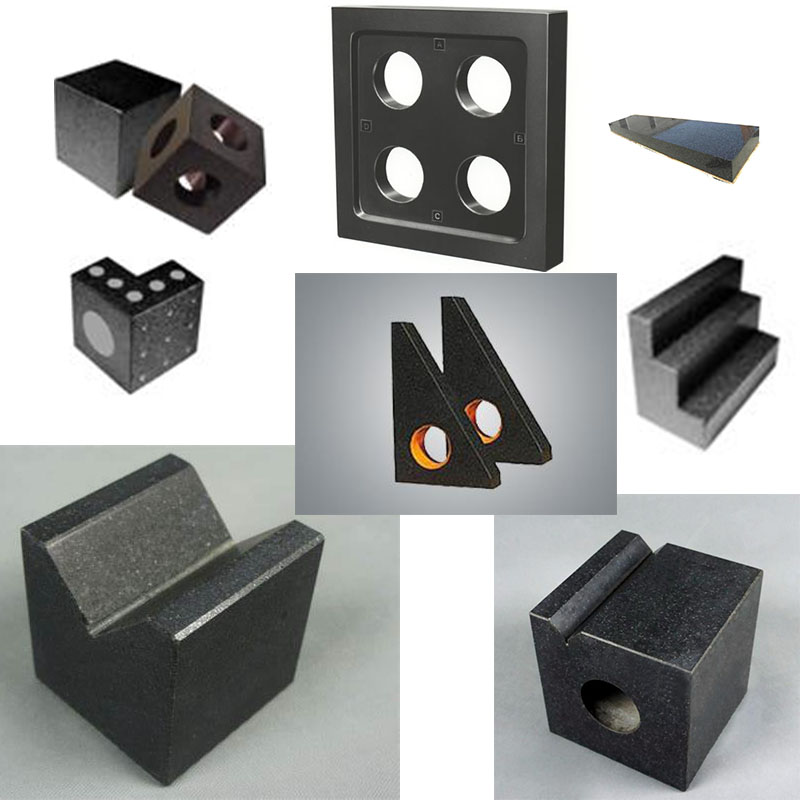

A surface plate is a solid, flat plate used as the main horizontal reference plane for precision inspection, marking out (layout), and tooling setup.[1] The surface plate is often used as the baseline for all measurements to a workpiece, therefore one primary surface is finished extremely flat with tolerances below 11.5 μm or 0.0115 mm per 2960 mm for a grade 0 plate.[2] Surface plates are a common tool in the manufacturing industry and are often fitted with mounting points so that it can be an integrated structural element of a machine such as a coordinate-measuring machine, precision optical assembly, or other high precision scientific & industrial machine. Plates are typically square or rectangular, although they may be cut to any shape.

here are varying grades used to describe the accuracy of some metrology equipment such as: AA, A, B, and Workshop grade. While workshop grade is the least accurate, the plates are often held to a high degree of flatness.

Surface plates must be calibrated regularly to ensure that chipping, warping, or wear has not occurred. A common problem is wear to particular areas, such as that caused by the frequent use of a tool in one place (such as a height gauge), that causes an uneven surface and reduces overall accuracy of the plate, this may be greatly accelerated if abrasive dust is present. Tools and workpieces may also cause damage when dropped on the surface plate. Also, damage can be caused when swarf and other debris have not been removed. This will result in erroneous measurements. Damage to the plate can only be corrected by resurfacing which requires specialised techniques and equipment depending on the grade of the plate.

Granite surface plate calibration should be performed routinely to maintain proper flatness and ensure measurement accuracy over time. The intervals between calibrations depends on the environment where the surface plate is located. When needed, lapping or resurfacing is provided to bring measurements within grade guidelines. This procedure involves polishing the surface with an abrasive paste to remove all unwanted material. Granite surface plate calibration also includes cleaning and a light polishing.

CATEGORIES

LATEST NEWS

CONTACT US

QQ: 1875871537@qq.com

Phone: +8613922886486

Tel: +8613922886486

Email: 1875871537@qq.com

Add: Shatou Industrial Park, Baoan District, Shenzhen City, China. Factory address: Liaocheng City, Shandong Province, China